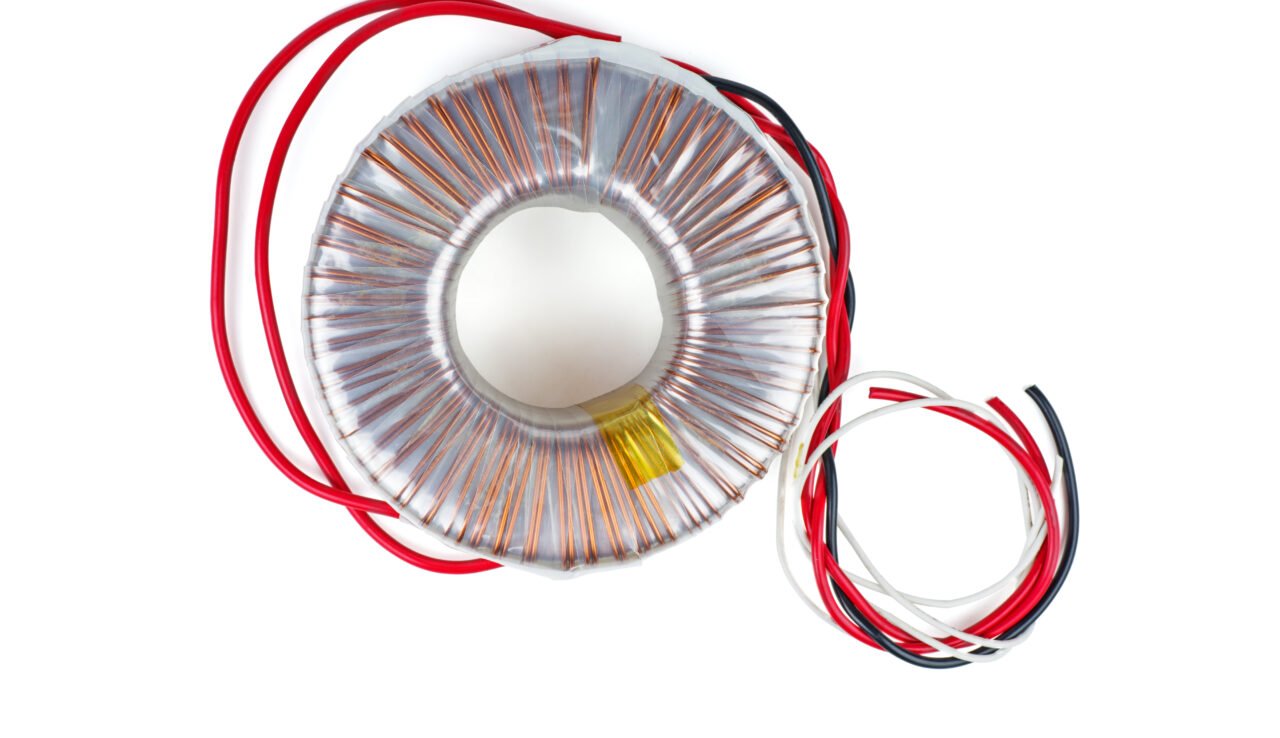

Medical devices require transformers that meet strict safety standards to prevent electrical hazards to both patients and operators. These transformers must comply with the Medical Devices Directive (MDR) and relevant standards like EN60601-1, ensuring proper isolation and protection against electrical faults. They must deliver a stable power supply to ensure the reliability and precision of medical equipment, particularly in high-precision devices like MRI machines and ultrasound systems. Additionally, transformers should have low noise levels to maintain a quiet environment, reducing distractions for patients and ensuring the smooth operation of sensitive equipment.

Why Estable?

Estable is a leading manufacturer of medical isolation transformers and power supplies. Since 2004, its product has met the Medical Devices Directive (MDR) and EN60601-1 standards. With over 100 models ranging from 50 VA to 3500 VA, Estable also offers earth leakage guards (ELG) and network isolators (MLI) which support IT power supply systems in medical environments like operating theatres. Estable is a trusted supplier to global manufacturers of medical devices such as MRI machines, ultrasound equipments and C-arm X-ray machines.

Reliability

ISO 9001 2015 qualified, CE/UL/GS/CQC certification, 8-process quality control before delivery.

Flexibility

Customized Specification, Flexibility in quantities, 7*24 rapid response. International service team.

Efficiency

Immediate proposal, fast quotation, fast sample delivey, samples ready in 3 days.

Transparency

Transparent pricing, know our factories, know your cost, always ask why.

How does it benefit your product?

Transformers are essential for medical devices because they provide safe electrical isolation, protecting both patients and healthcare workers from electric shocks. They ensure a stable power supply, which is crucial for the precise operation of sensitive equipment like MRI machines and ultrasound systems. By minimizing electrical interference, transformers help maintain the accuracy and reliability of medical devices. Additionally, low-noise transformers create a quieter environment, improving patient comfort and reducing distractions during medical procedures.

- Low Power Consumption

- Low Noise & Vibration

- Space-Saving

- Superior Thermal Management

- Reliable Electrical Isolation and Safety

- High Electromagnetic Interference (EMI) Resistance

Frequently asked questions

In the medical equipment industry, transformers face some common and noticeable questions that are often raised.

What safety standards do medical device transformers need to meet?

Medical device transformers must comply with strict safety standards, particularly EN60601-1, which is designed for the electrical safety of medical devices. This standard ensures that transformers provide effective electrical isolation to prevent electrical shocks and function reliably in various medical environments.

Additionally, transformers must meet other standards like IEC 61558, which further ensures safety in medical settings, allowing transformers to operate safely over extended periods without failure.

How do medical device transformers ensure stable power?

Medical device transformers maintain stable power by converting unstable electrical input into a consistent output suitable for medical equipment. They often include overload protection to prevent damage from voltage fluctuations or excessive current.

High-quality medical transformers use low-loss materials and precision electromagnetic design to boost efficiency, ensuring stable and reliable power for sensitive equipment like MRI machines, ultrasound devices, and surgical tools. This stability is crucial to maintain the accuracy and reliability of medical devices during operation.

Do medical device transformers produce noise?

Medical device transformers can produce a small amount of noise, mainly due to electromagnetic vibrations within the transformer. However, to minimize disruption in sensitive environments, many high-quality medical transformers are designed to operate quietly.

They use special electromagnetic materials and casing techniques to reduce noise and electromagnetic interference (EMI).This low-noise design is essential in medical settings like operating rooms and diagnostic areas, where a quiet environment is crucial for patient comfort and smooth medical procedures.