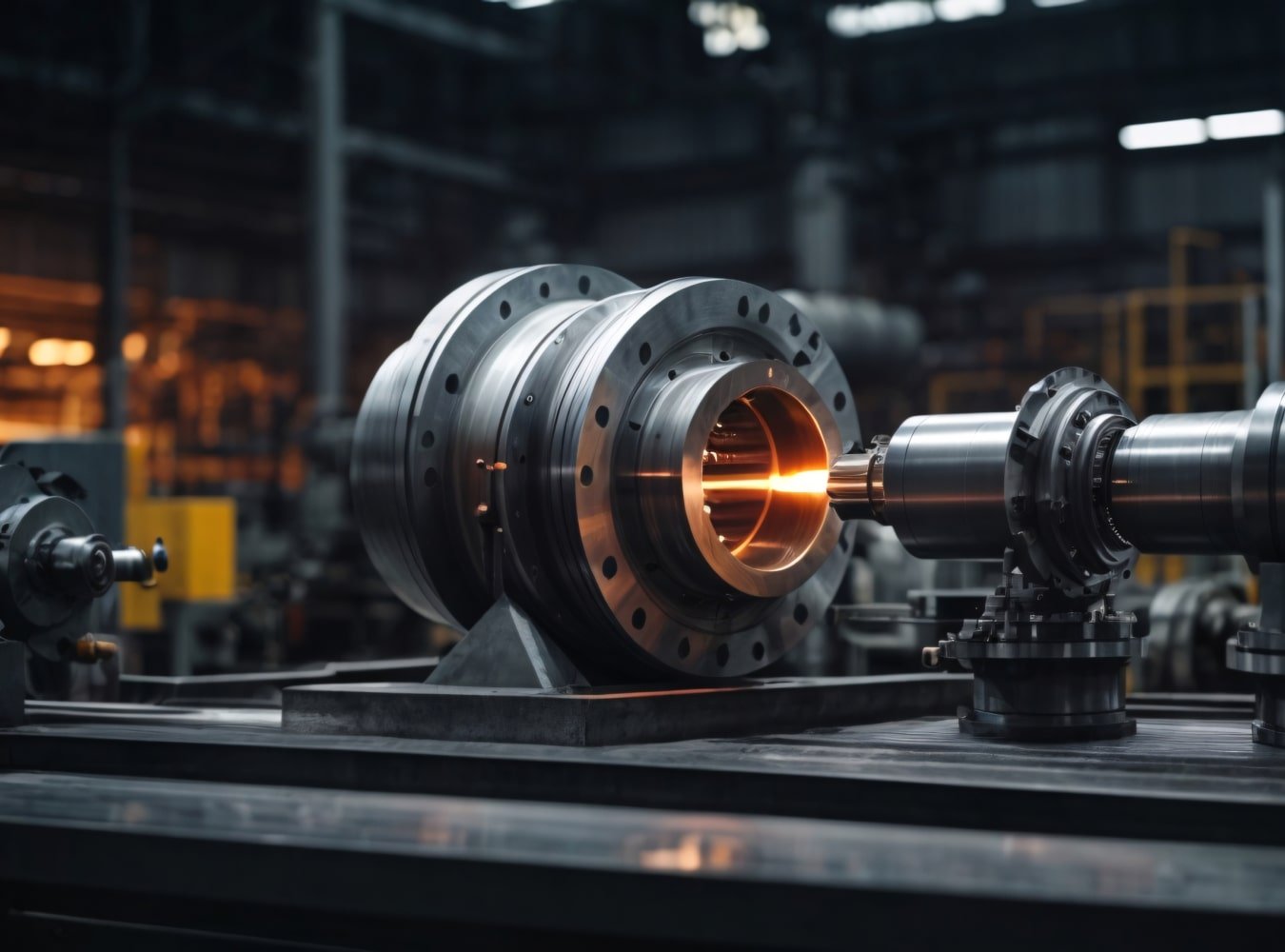

In renewable energy applications, high efficiency is one of the strongest reasons for choosing toroidal transformers. Because solar and wind power depend on varying conditions, every watt of energy counts. Toroidal transformers maximize power output by minimizing energy loss, ensuring more effective use of the harvested energy. This efficiency also reduces heat output, which helps extend the life of inverters and lowers maintenance costs. Plus, stable performance under fluctuating loads enhances overall system reliability, making toroidal transformers ideal for renewable energy systems.

Why Estable ?

With specialized expertise in solar and wind power, Estable provides the renewable energy industry with a range of component solutions. Our transformers are designed to deliver reliability in the most challenging environments across wind, tidal, and solar energy applications.

Our deep understanding of the renewable sector has driven Estable to develop solutions that meet the industry’s demands for low energy losses, high efficiency, high energy density, and compact size. These often-conflicting requirements are addressed through designs that leverage cutting-edge materials and advanced topologies.

Each meeting stringent environmental standards for corrosion protection, vibration stability, and long service life. All solutions are fully tested under strict quality controls to ensure optimal performance.

Reliability

ISO 9001 2015 qualified, CE/UL/GS/CQC certification, 8-process quality control before delivery.

Flexibility

Customized Specification, Flexibility in quantities, 7*24 rapid response. International service team.

Efficiency

Immediate proposal, fast quotation, fast sample delivey, samples ready in 3 days.

Transparency

Transparent pricing, know our factories, know your cost, always ask why.

How does it benefit your product?

Their compact, lightweight design saves space and integrates easily into equipment with limited room, such as EV charging stations and solar inverters. They also produce minimal noise and vibration, supporting quiet operation and meeting environmental standards.

- Low Power Consumption

- Low Noise & Vibration

- Space-Saving

- Superior Thermal Management

- Reliable Electrical Isolation and Safety

- High Electromagnetic Interference (EMI) Resistance

Frequently asked questions

In the renewable energy industry, transformers face some common and noticeable questions that are often raised.

How do you optimize transformer efficiency to reduce energy loss in clean energy applications?

To cut down on energy loss in transformers running at high frequencies, we’ve focused on a range of technical optimizations. We start by using high-permeability core materials that reduce hysteresis and eddy current losses. Additionally, our winding design is optimized to keep the magnetic flux more evenly distributed, which helps cut down on leakage losses and boosts efficiency.

For renewable energy setups like solar and wind systems, we also incorporate low-loss topologies with multilayer windings and high-quality insulation to minimize losses further. These design improvements increase power density and conversion efficiency. Plus, our thermal management techniques help maintain steady temperatures, ensuring stable, high-performance transformer operation even in high-power, high-frequency conditions.

How can EMI resistance be enhanced to ensure system safety and stability?

To enhance EMI resistance and ensure system stability, we optimize the winding arrangement by using specialized structures and configurations that promote a more uniform magnetic flux distribution within the transformer. This reduces leakage effects and minimizes interference with other electronic devices. Additionally, we use high-performance insulation materials, which reduce the pathways for electromagnetic interference and further improve the system’s EMI resistance, especially in high-voltage environments.

What are the key design factors for creating a low-noise, low-vibration transformer?

To design a low-noise, low-vibration transformer, we focus on several practical approaches. First, we optimize the winding design by using compact windings and ensuring a uniform magnetic flux distribution, which helps reduce both noise and vibration. We also select high-quality core materials with low losses to minimize hysteresis and eddy current losses, further lowering noise levels. To address vibration, we incorporate damping materials and vibration isolation mounts, reducing external effects. Additionally, the transformer’s casing is built with soundproofing materials to prevent noise from spreading. Together, these strategies ensure quiet, stable operation.